Wiring up the gearbox chassis

Now that I had a set of 4 at least minimally working lateral servos, I needed to wire up the chassis so that everything had power and data. Here are some pictures of that process:

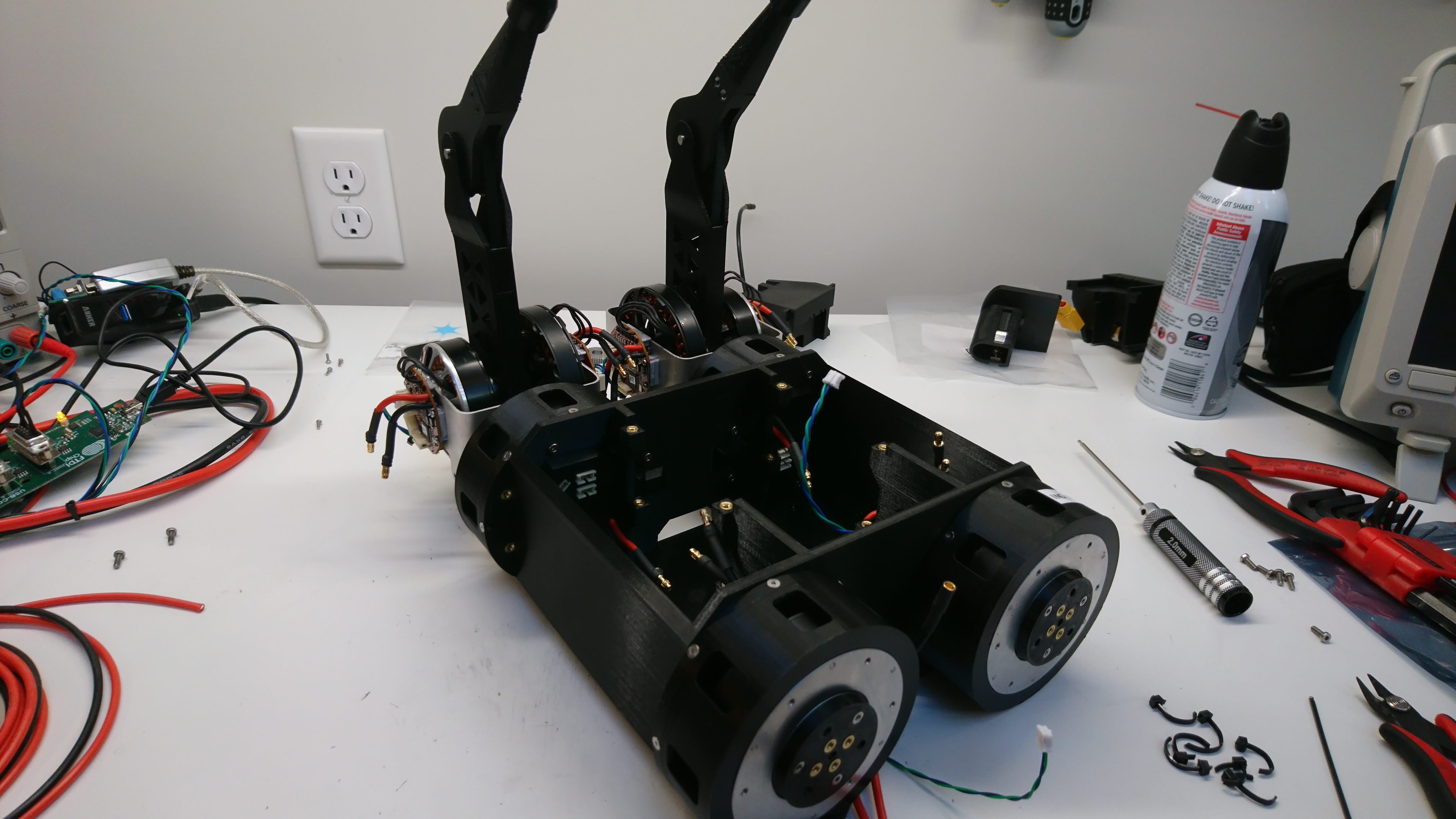

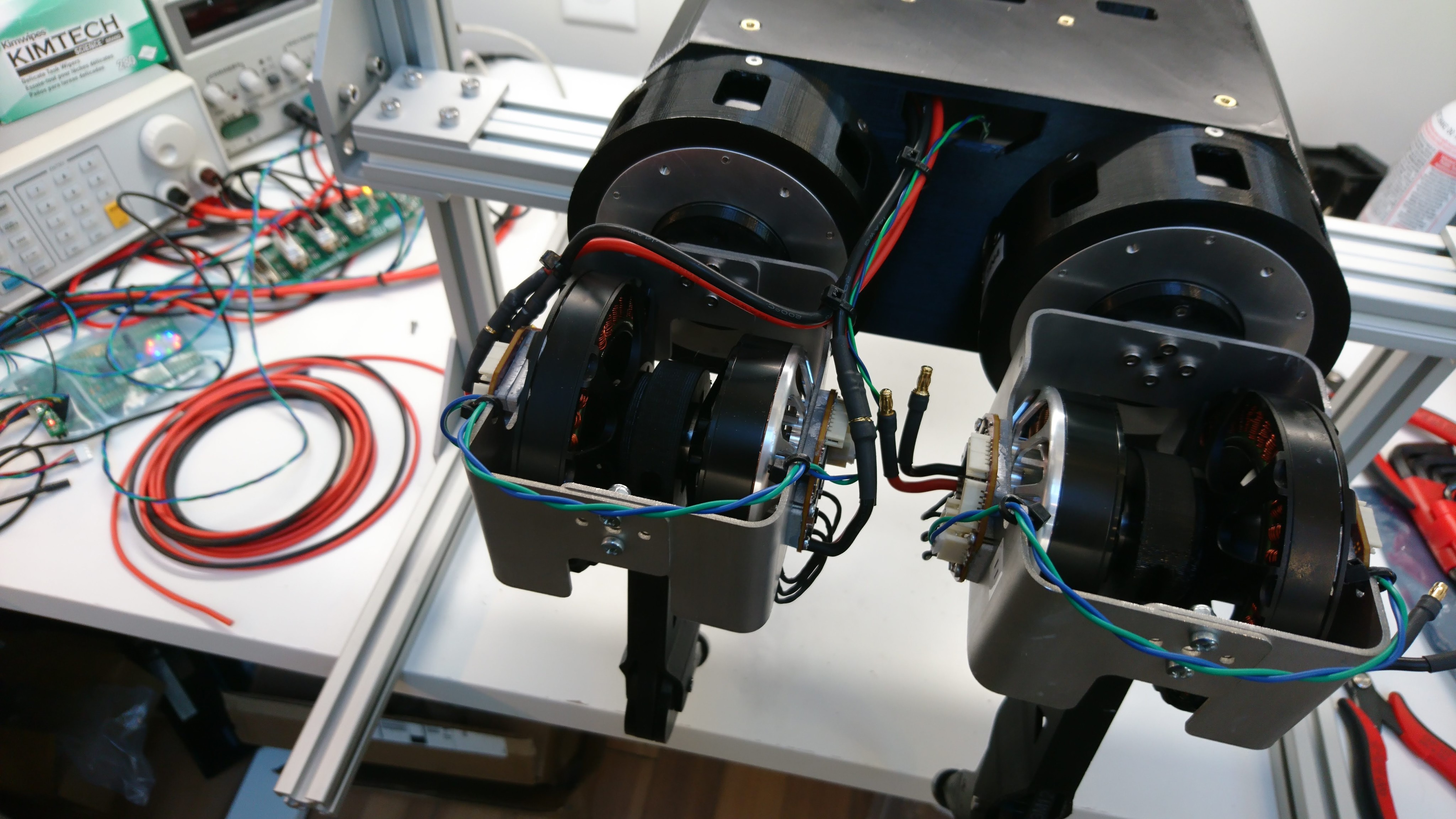

Two legs installed

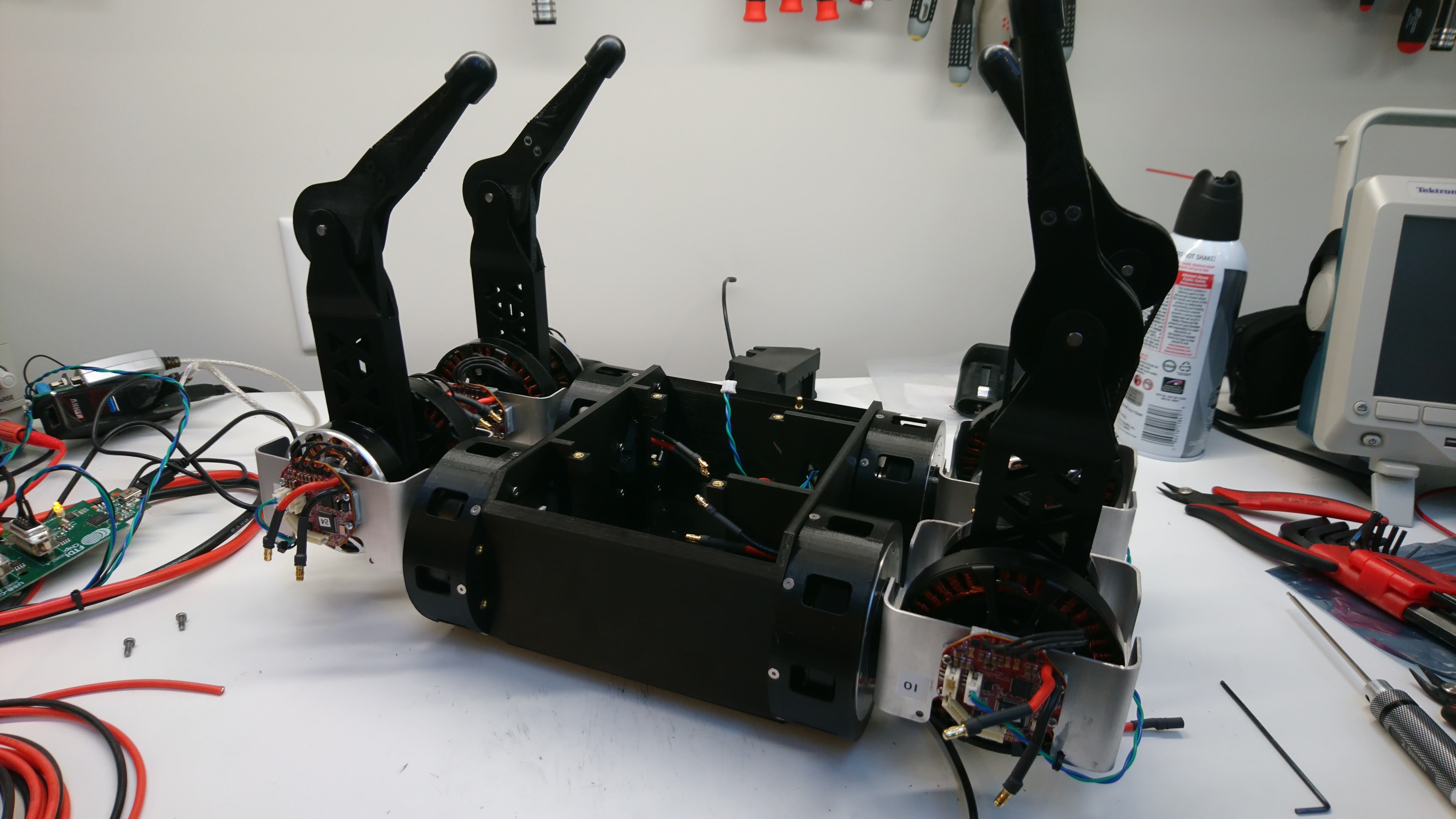

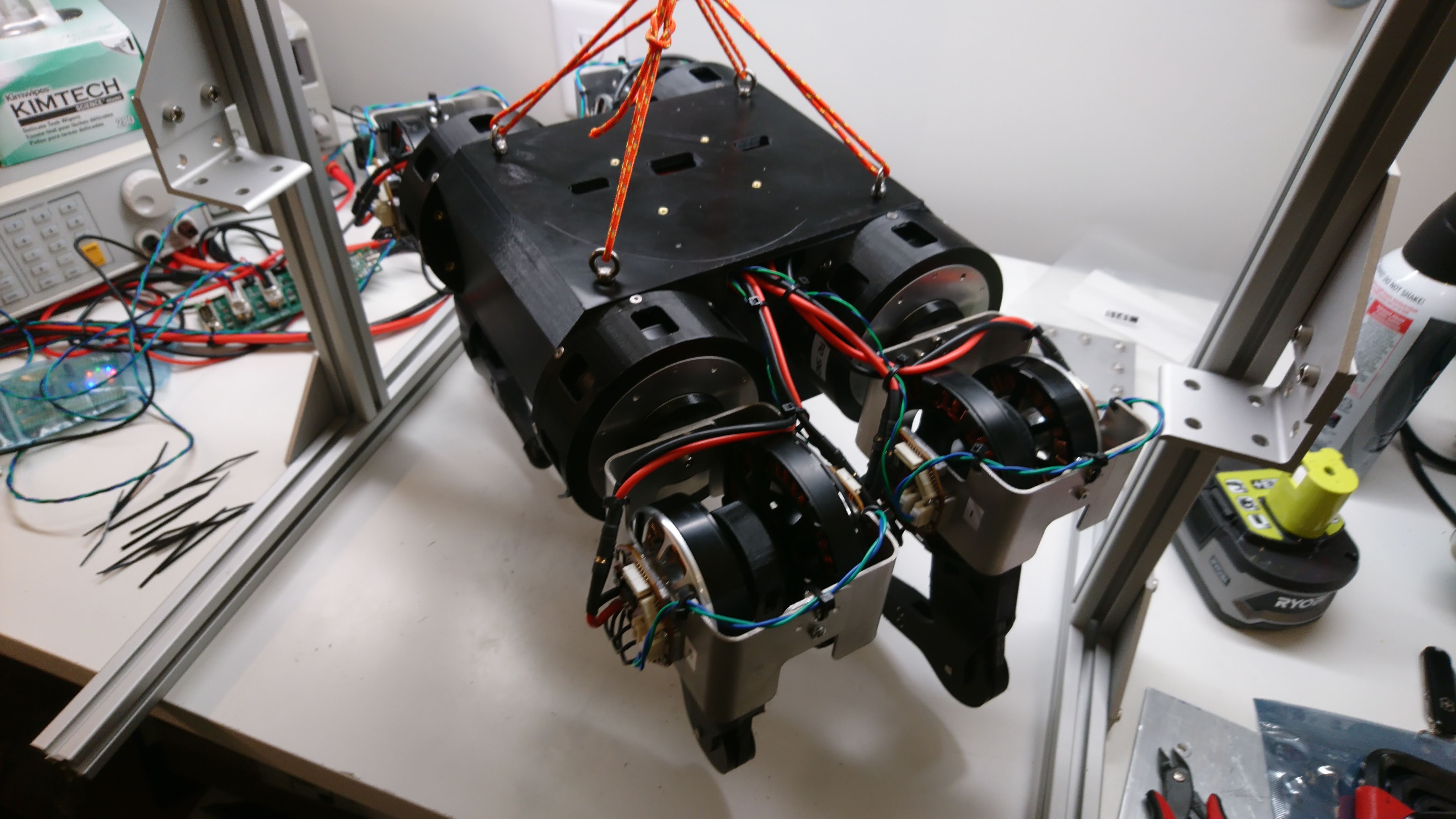

Four legs installed

Joint cable routing

Times four

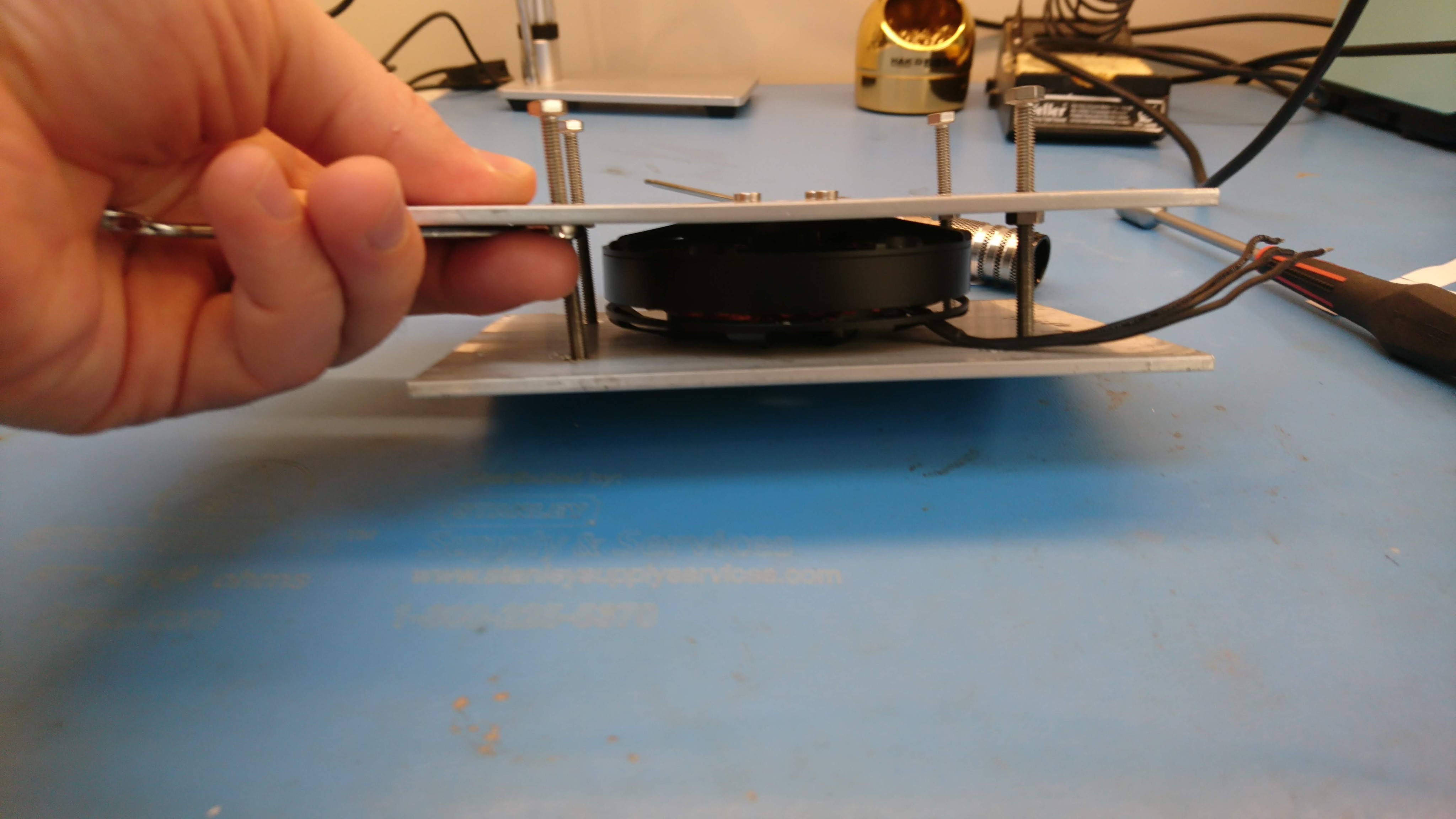

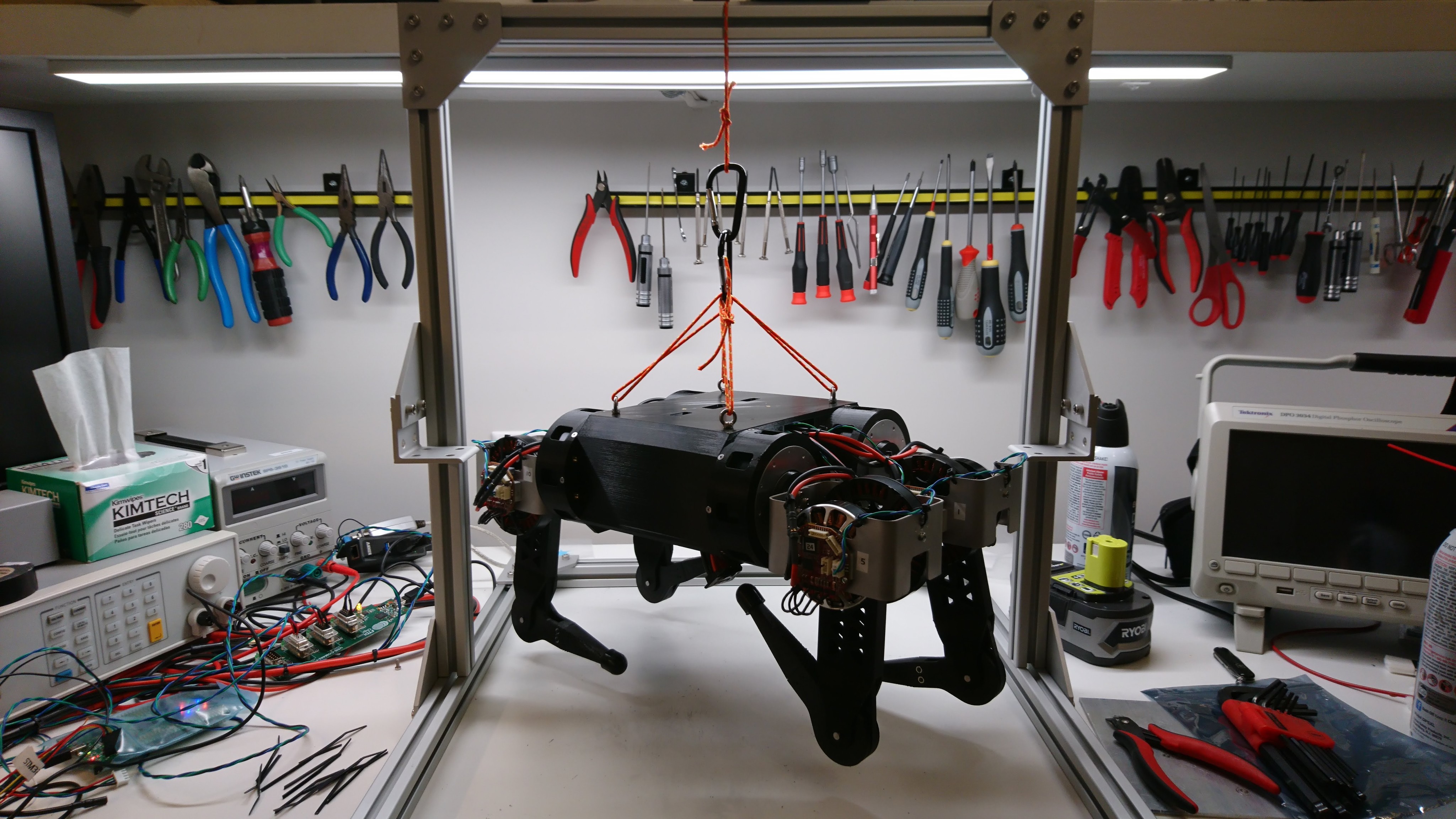

Suspended from the test fixture

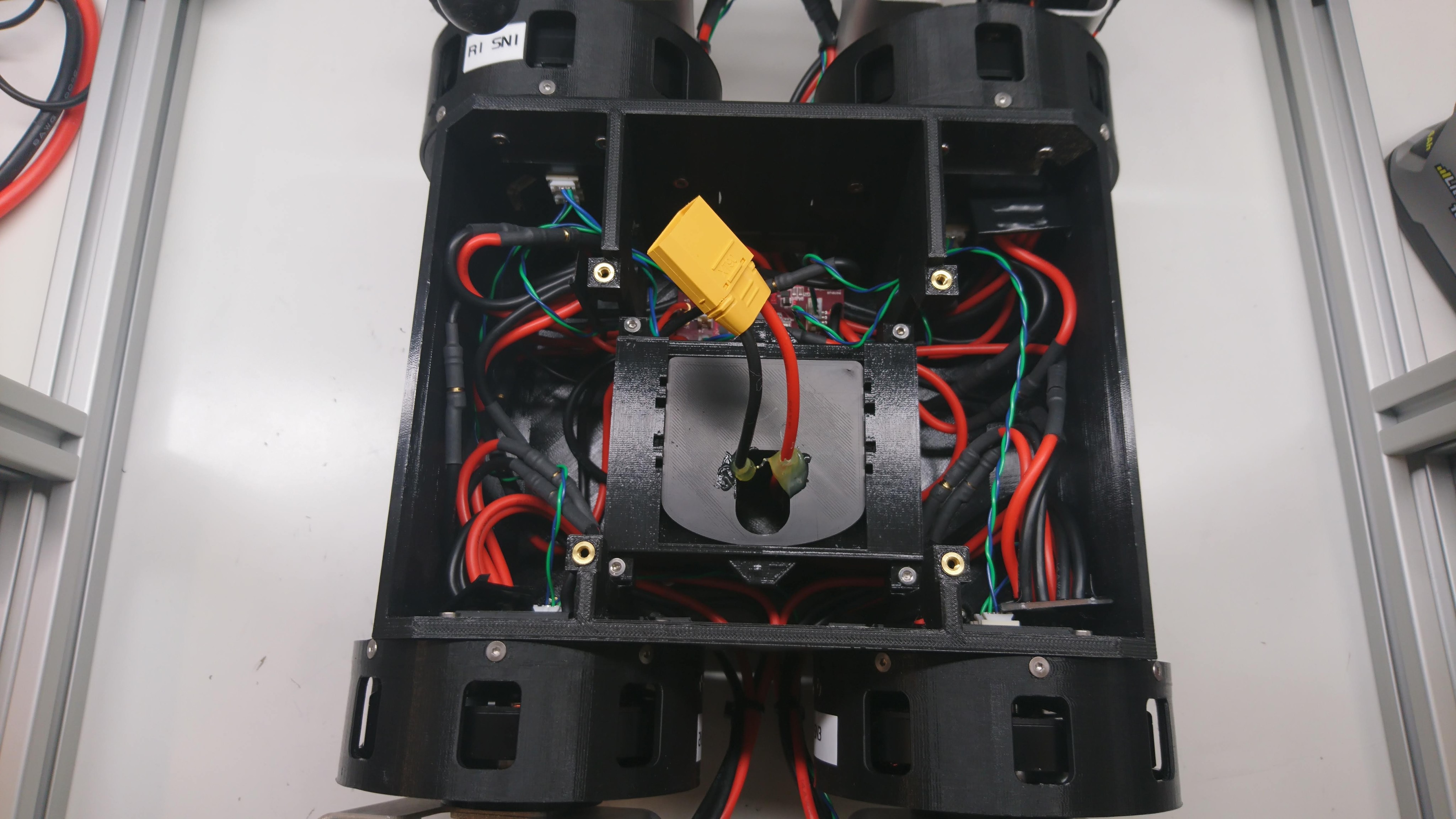

Four sets of busbars, the junction board, and a shore power battery simulator