First walking on the full rotation quad

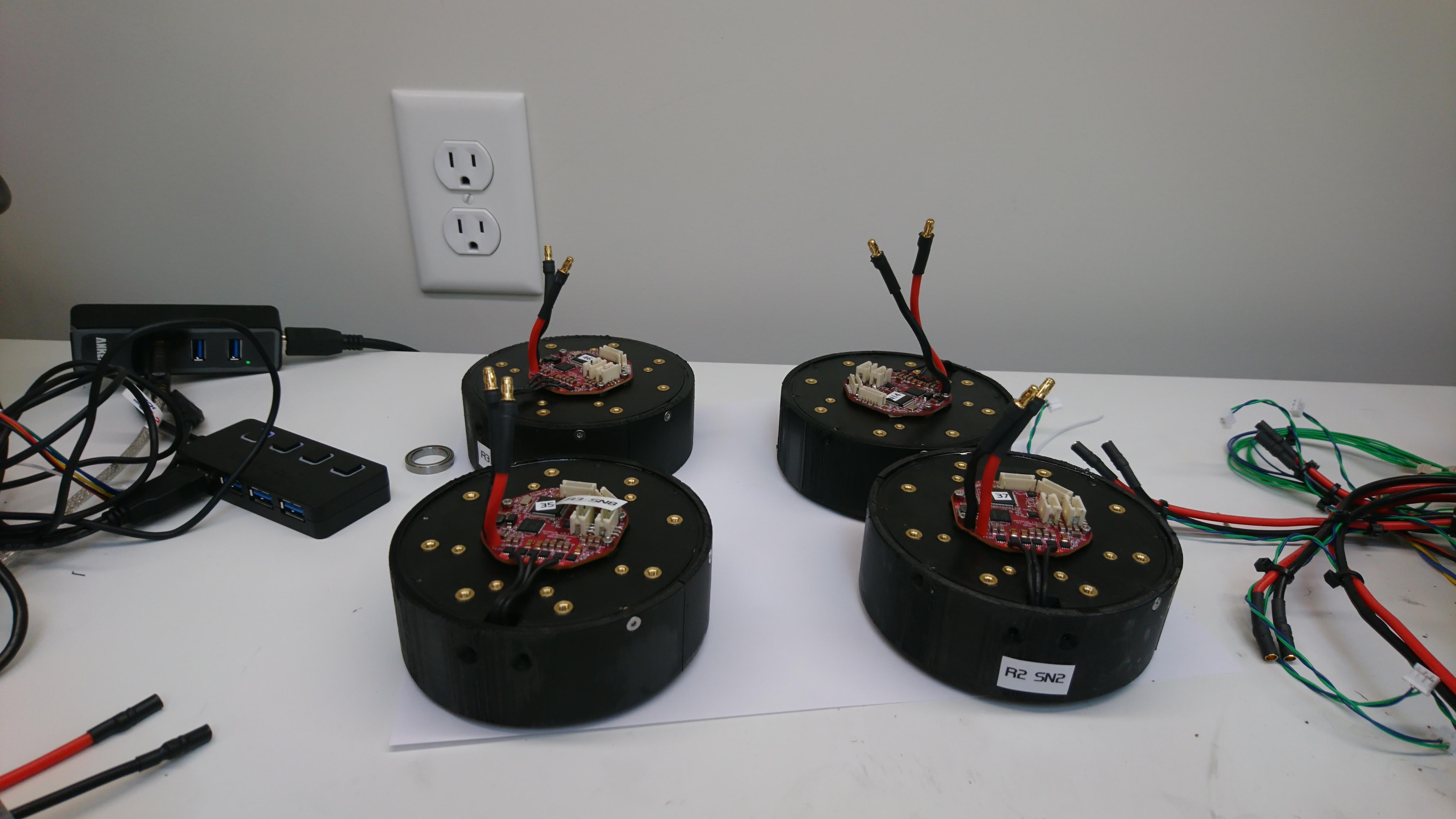

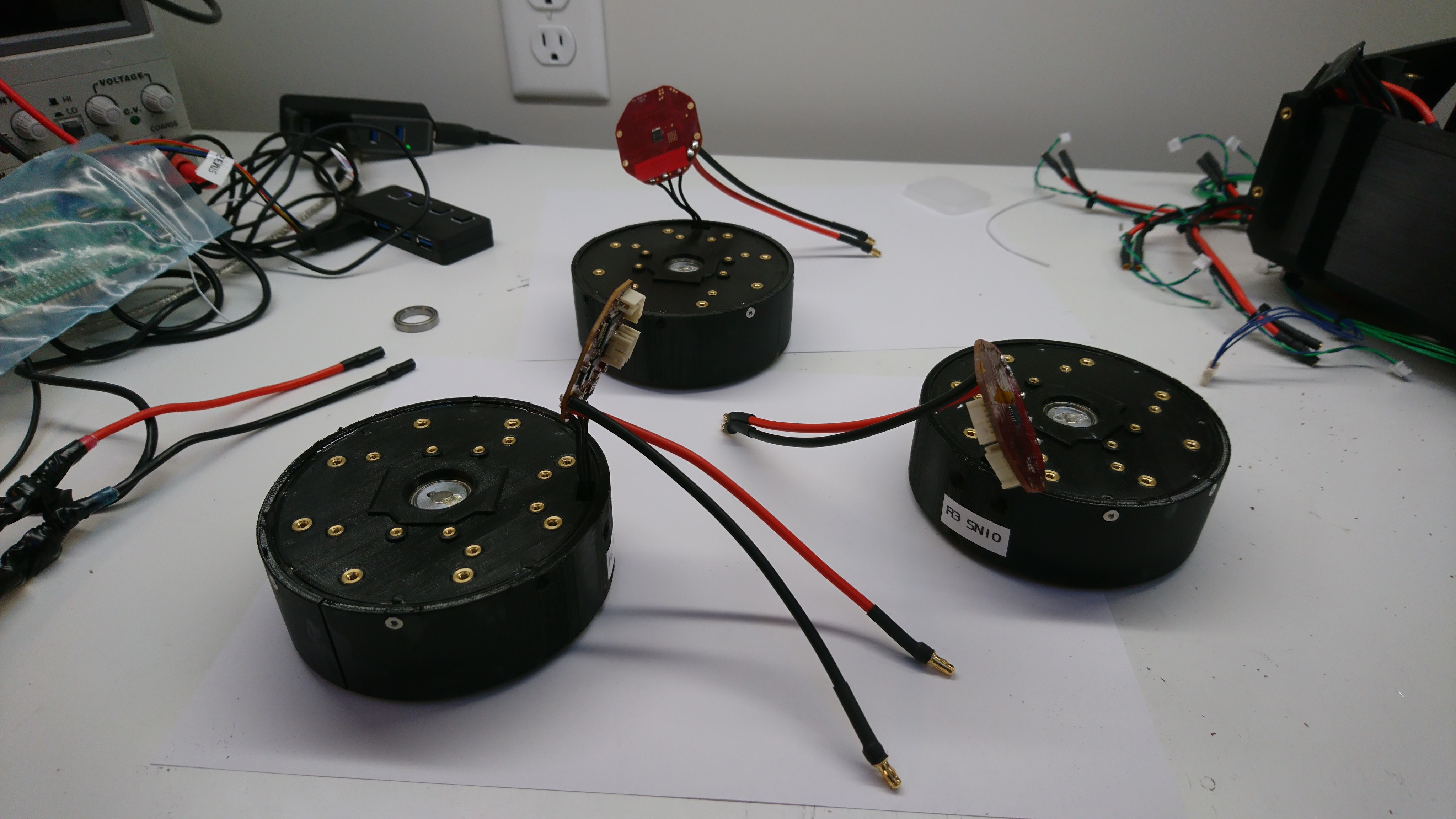

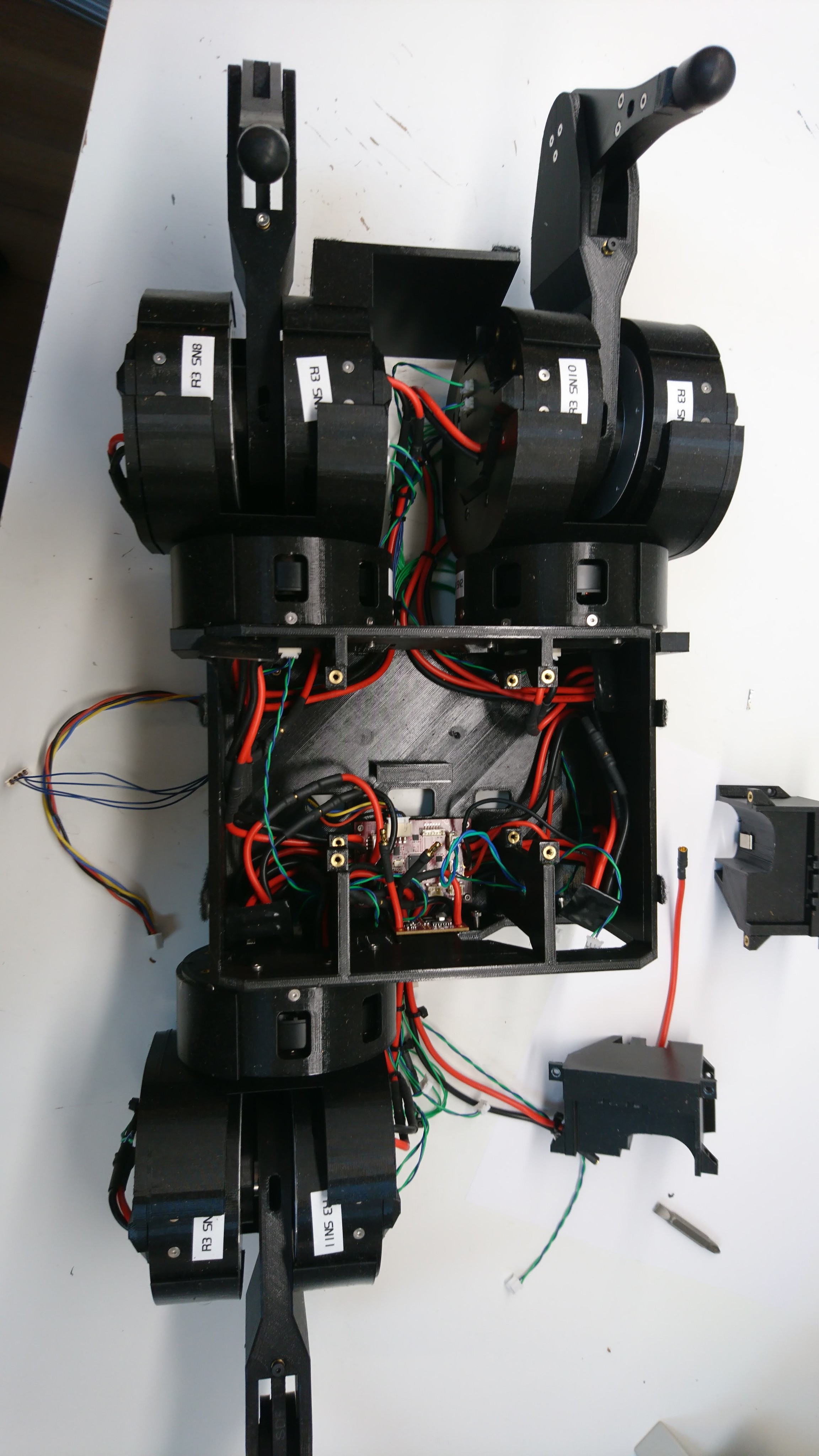

Last time, I had finished physically assembling all the motors for the updated quadruped with legs that can rotate freely 360 degrees. After the long summer break, I powered up and configured all the servos. Then, after setting up the gait engine for the new configuration (for which there are still a TODOs when the lateral shoulder offset is non-trivial as in this configuration), I was able to achieve some amount of walking. Here is one of the first videos I took, without much in the way of tuning or work. The control is a little wobbly still, but so far there are no signs of any mechanical failures as with the older design.