Bringing up the IMU on the pi3 hat

The next peripheral to get working on the quad’s raspberry pi interface board is the IMU. When operating, the IMU will primarily be used to determine attitude and angular pitch and roll rates. Secondarily, it will determine yaw rate, although there is no provision within the IMU to determine absolute yaw.

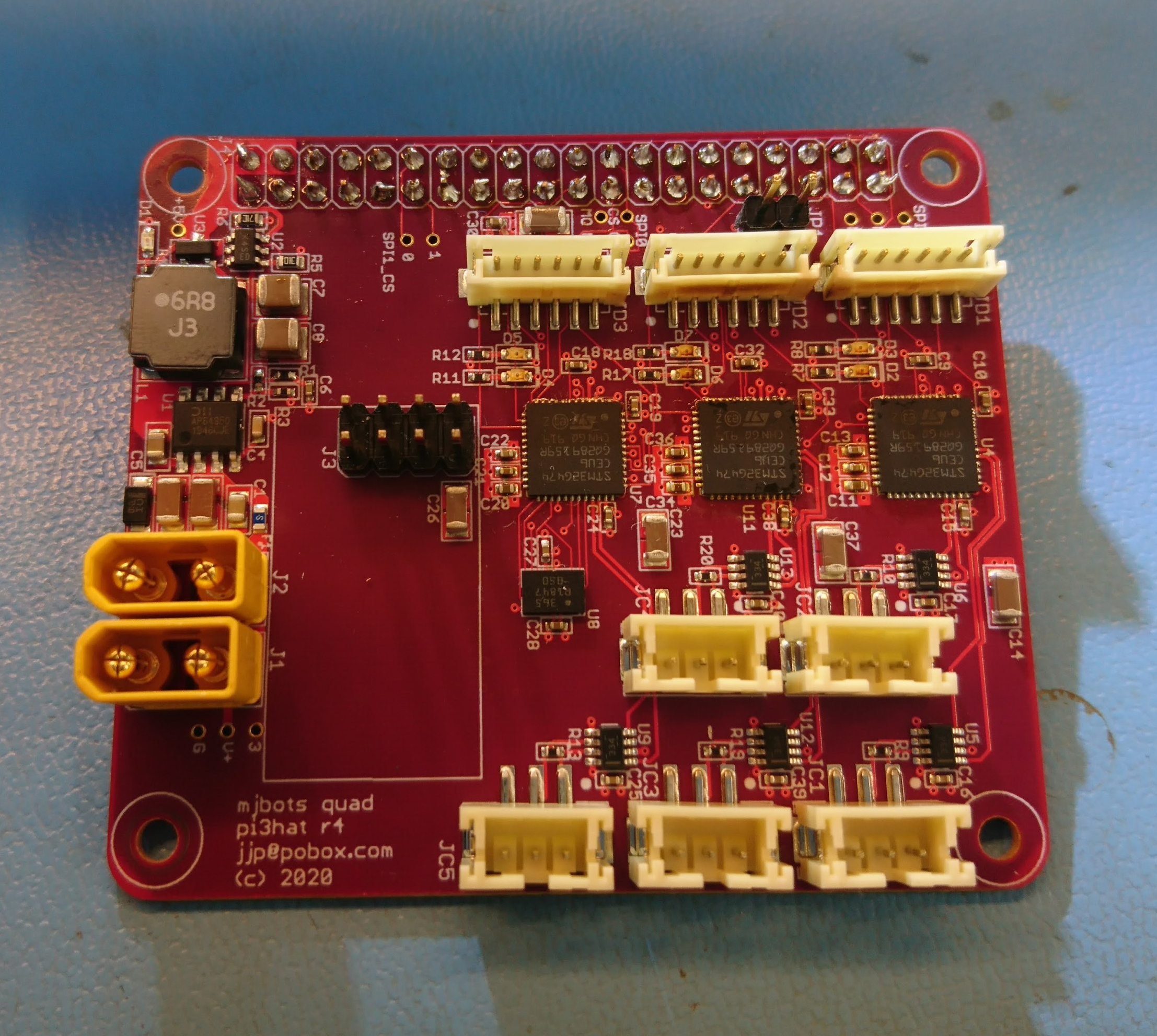

To accomplish this, the board has a BMI088 6 axis accelerometer and gyroscope attached via SPI to the auxiliary STM32G4 along with discrete connections for interrupts. This chip has 16 bit resolution for both sensors, decent claimed noise characteristics, and supposedly the ability to better reject high frequency vibrations as seen in robotic applications. I am currently running the gyroscope at 1kHz, and the accelerometer at 800Hz. The IMU is driven off the gyroscope, with the accelerometer sampled whenever the gyroscope has new data available.